this was an entire project of its own

Over the years I have acquired several benchtop tools which, with my limited garage space, required me to setup a table, carry the tool out, some of them are heavy/bulky awkward bastards ( & I’m not getting any younger), which eventually got the better of me & I though bugger it, build a fliptop bench to hold all the tools so I don’t have to do anymore heavy lifting.

The problem was I also needed workspace, so having double occupancy of each fliptop station wasn’t really an option, so I had to increase the number of fliptop stations to accomodate each individual tool.

I managed to acquire enough design ideas & inspirations from several youtube content creators to come up with a working design to suit my requirements.

The bench design isn’t for everyone, it’s big, some would argue too big, in height & width, you cannot lean across it to grab things from either side…. & the height, determined by the minimum dimensions to allow the tallest of the tools perform a flipover & neatly stow is probably too high for the purists.

It’s heavy, I can manage to push it around on a smooth flat surface, but pushing it up the slight incline of my driveway wasn’t getting any easier for me, so I opted to put a motorised trailer jockey wheel on the end of it, so that I wouldn’t hurt myself trying to use it after I had built it…

details of the build project are included below – enjoy.

workbench project

I have recently completed a large woodworking bench to house all my benchtop tools.

it has taken quite a bit of time to assemble all the tools, & scrap wood/seconds to complete

even then its still cost me a couple hundred $$$ in hardware bibs & bobs

when everything is housed it provides a large flat benchtop with PARF holes (done with a jig)

the mitre saw & planer thicknesser pivots are recessed lower than the 4 end flip-tops, this is to allow the machines work surface to be flush with the benchtop when in use.

so i had to build some insert sections for when the machines are stowed

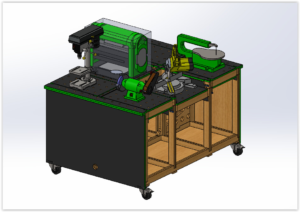

currently I have a bench grinder & drill press at one end,

the mitre saw & planer/thicknesser in the middle (obviously)

& the other end i currently only have a belt sander & an oscillating bobbin sander

with one flip-top still vacant (holding out of a bandsaw…

the oscillating bobbin sander is on a drawer the slides out mounted directly underneath the belt/disc sander, there is just enough room house them both & for them to move out to their operational points

(i dont have a scroll saw as illustrated here),

I’ll take some photos of the real thing next sunny day we have, I have to wheel it out of my garage to use it, the driveway is on a slight angle & this beast is heavy.

dimensions are bigger than suitable for a work bench

it has to be to accommodate all the tools mounted in it

its also a little higher than it should be (optimally) as the drill press needs to be able to clear the bottom & the weight of the bench dictated i use larger wheels (normally pushing ■■■■ uphill – literally, to get this back inside at quittin’ time)

Design Considerations

Originally I had planned the design to utilise some cheap plywood non-structural plywood, I figured I could glue them together to make reasonably sturdy frame, but then a mate pulled down a small mezzanine office in his warehouse & i grabbed all the frame lumber to repurpose it. (score!)

All the plywood is also sourced from same bloke, where a local technical training institute relocated to new facilities & had lots of heavy machinery delivered in large pallet boxed up with 19mm ply (score again!) lots of it was damaged or delaminating at the edges, but trimming off the crap still left me with some substantial pieces to play with, i ended up with almost a metric tonne of lumber & plywood sheets, I actually had to upgrade the wheels on my lumber cart twice to cope with the weight.

So the bench itself is BIG, ergonomically its a “fail” because of the sheer dimensions i required of it to fit all my benchtop tools in. Its also very heavy & Im looking at getting one of those battery powered trailer dollies to stick on one end so that i don’t have to literally bust a gut getting it back in the garage.

I can manage it at the moment, but can see the day in the not too distant future where i either cannot or give myself a hernia trying…

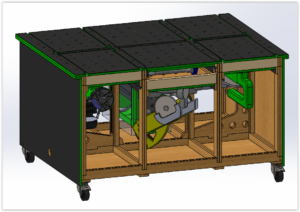

Flat top bench mode: everything folded away. all tools stowed

note: the vice grips the edge of the top & can be removed it it gets in the way

at the opposite end the clamps will probably end up on a small piece of wood for the purpose to remove them potentially obstructing, also the little silicon trays are a good thing, you tend to get accustomed to working on a single ‘pivot station’ & keeping everything on a large tray or offcut so that you can pick everything up & relocate it if you require access to the tool underneath where you’re working

note the power inlet, once this is plugged in, all tools in the bench are now live as well as the additional power outlets at each end (inside & underneath).

Sparx

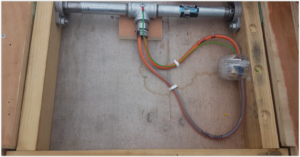

All of the flip-top stations are wired similarly as pictured.

This was the most painful part of the whole assembly, as i had to juggle & stagger the pieces just right in order to get them in place & functional.

Lots of storage underneath, i am still determining the best option for this hence I haven’t arranged the trays into a static holder, as I’m not sure of the dimensions for the last remaining tool to be placed.

Here you can also see the variation in height of the center pivot stations & the insert sections to provide a smooth top

You can see the oscillating belt/bobbin sander, I couldn’t put it on a flip-top as all the components fit in the base (which I find quite handy), so opted to leave it upright & tweeked the positioning of the bench grinder to accommodate both tools

A simple locking mechanism for when the tools are upright so that they don’t suddenly ‘move’ on you whilst being operated.

spring loaded pin & chipboard insert in the leg.

now for the fun part, all the tools opened (except the missing one)

the wood tools end…

Mitre saw extension allows for longer pieces to be handled easier & had to also consider which tools would be located where, so that if I need to use multiple tools at the same time it wouldn’t put me at a disadvantage & be constantly flipping over tools/packing up , only to have to do it all again.

blank is currently intended/reserved for a bandsaw(don’t want a ryobi though – dodgy), most likely & its doubtful that I would be using the mitre saw then the band saw in unison, however mitre saw + belt sander, or bandsaw + belt sander – very probable.

The planer thicknesser in operating position

Note: the pivot base is lower than required & I’ve had to pack spacers underneath it (same for the mitre saw)

This is due to the fact that these are not my optimal machines & should they die prematurely & i have to replace them – i made sure that the pivot centers would allow for the ones I want Santa to bring…

Upgrades/wishlist

(dewalt planer/thicknesser with a spiral cutter…(yummy)

& bosch compound glide saw…engineering pr0n,…)

woof!

Because the center pivots are recessed lower than the benchtop I could capitalise on this & put different locking mechanisms for when the 2 center machines are operating.

simple, cheap & effective.

the metal work end…

I placed the drill press & the bench grinder at the same end so that if I’m working on anything metallic, I wouldn’t have to do laps around this enormous bench

Note: the foot pedal cutoff, for the drill press – handy, because the table I made for the press is pretty much in your face in its current config, but its kind of unavoidable

I cannot lower the bench because the drill press only just fits

note the plastic bag to cover the motor… lots of crap will go straight into it otherwise. (this design doesn’t have any integrated dust collection).

Putting it away at the end of the day… everything is on wheels so – it’s a big game of tetris…

so welcome to my nightmare

Left to Right

- Tool caddy on the left, top of lumber cart just visible behind it.

- Off-cut bins on a trolley, with the folding table saw behind that

- the garden tool trolley

Behind all of which is the bench, beside the bench behind the garden tools is the laser cutter,& behind the bench in the bowels… is the CNC router & my DIY dust collection unit.

One of these days I’ll get around to making a little walk around video & put in all the links to other YT videos that inspired my design.

There are some beautiful benches out there, that are finished superbly, but I’m more interested in function over fashion, as long as it does the job, & can cut straight /square / plumb – I could honestly care less what it looks like.

At end of the day this entire bench is made from recovered/scrap wood.

Don’t forget the site supervisor…

Doesn’t matter what/where you’re cutting, he always manages to lay right where the majority of dust/debris will find him.