- external

- canopy trim

- EFABs

I have accumulated a small stockpile of scrap plywood offcuts, mulitples of each in various sizes, they are stashed in a pile in the shed at my old family home, so I had to travel down to get them.

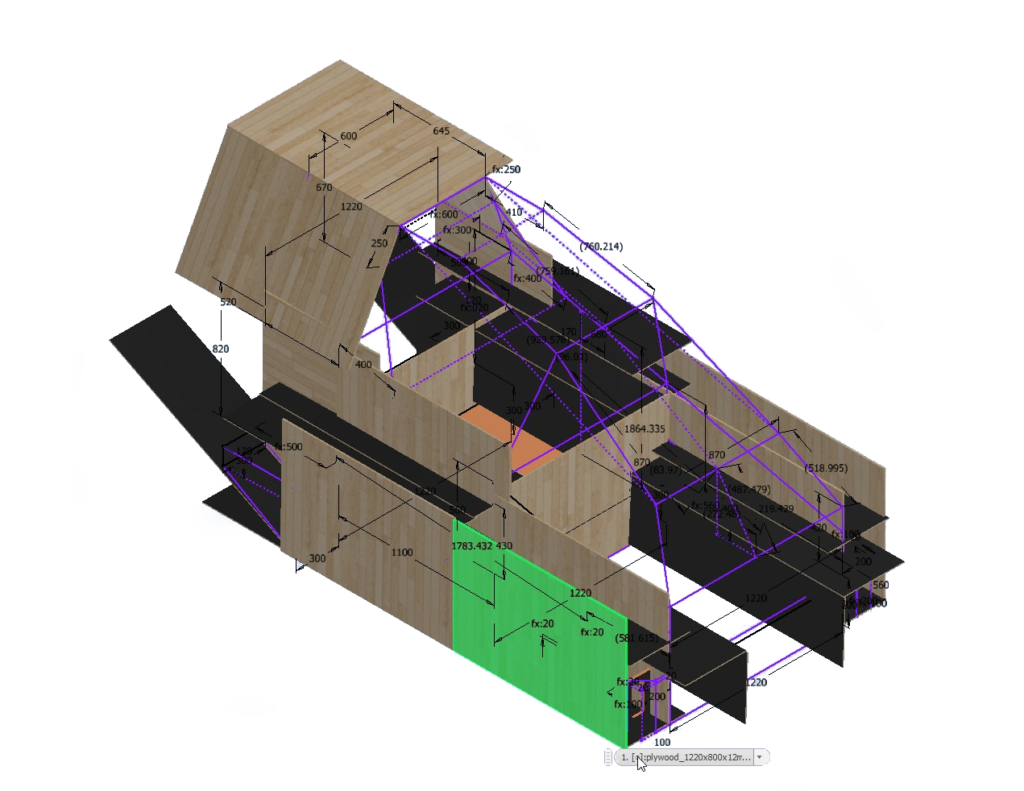

So the first thing i had to do is work out how many of each sized sheet I needed for each specific section, this was made easy by playing jigsaw with the 3D wireframe & placing multiple sheets to work out just how much plywood the shell would require.

It’s not pretty but it made it so much easier…

Once i had a sheet count of each sheet, (most are 10 or 12mm, the supporting braces are all 17mm). Once I had the ‘shopping list’ I knew what i had to pick up on the trip home, I also allowed ~20% on the count for any issues/breaks/mistakes/anomalies, just in case, to save me another trip.

I needed to get a baseboard for the frame to sit on before i started anything, so I used two of the largest 17mm sheets I could find, then I had to join them (this pit is a beast) then I doubled up on the thickness, overlapping the sheets so that there was some rigidity provided, then I placed the castor wheels underneath…. lots of castor wheels.

The steel frame had to be assembled & placed onto the base board & secured (screwed down) iin place to prevent it moving unexpectedly.

I started with the easy bits first, I made a raised platform for the PLT seat, this had to be very sturdy as it had to be able to take the static & dynamic weight of the G-seat & myself, being tossed about, this platform was also fixed to the baseboard.

I began placing trim around each station edge & on the canopy bars, as well as the diagonal sections on the PLT station. I was now planning out the EFABs

I had to allow for a sectioned EFAB as well, as the plywood sheets I had to play with were of limited lengths.

The starboard EFAB is lower than the port side, & is a bit more structurally sound, with the tops all 17mm ply instead of the 10mm on the port side. As this is the entry/exit side.

I applied a little primer, its amazing the difference a lick of paint will make, also put some of the handles in place that I had been accruing over the last few months

Sometimes its the little things….

With the the asymetric EFABs, the (interim) CPG dash & both seats in place… it’s starting to take shape.

It took a little extra fiddling about, but the chamfered edge & the grip handle add a lot of character to the port side of the pit, which is now my favourite.

There is a bit a whoopsie here, that I didn’t realise until i looked at a picture of a real apache, realising my mistake. Those with an eye for detail will spot the obvious, it doesn’t really matter, they are more for aesthetics than anything (not used). One day my OCD may get the better of me & I’ll rectify it.

I started putting together the PLT dash

Also made the CB panel for behind the PLT station