So it begins, into the rabbit hole we go….

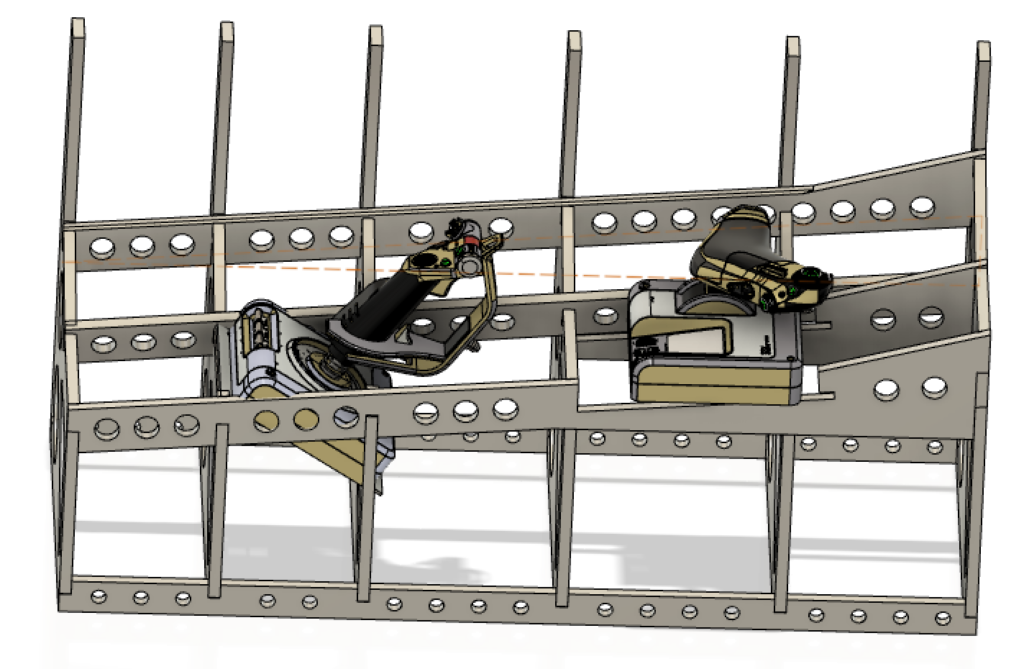

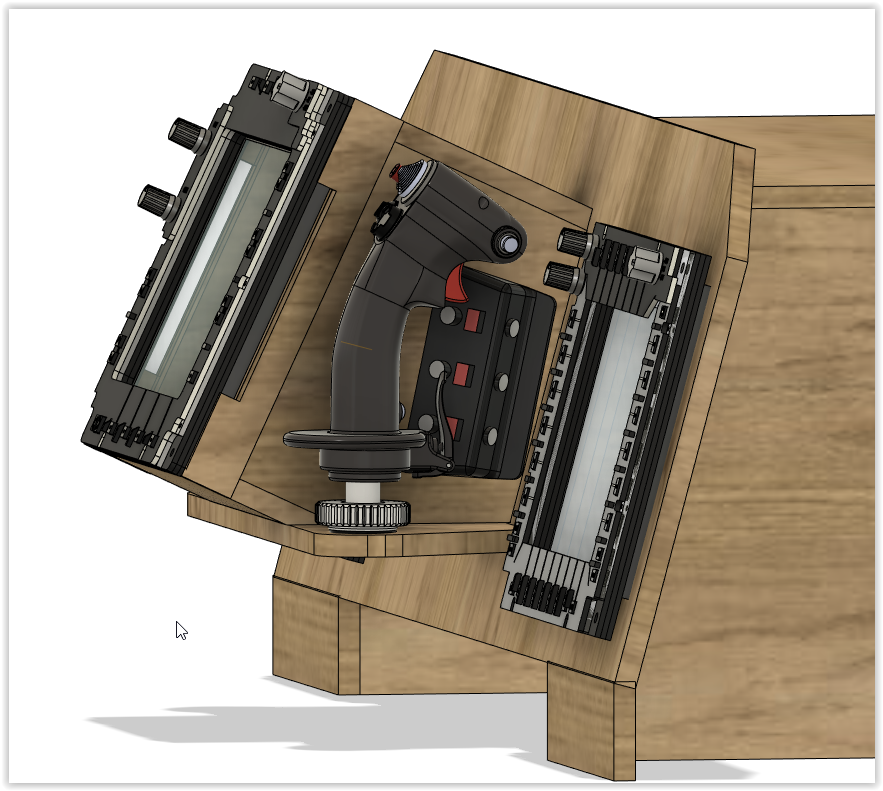

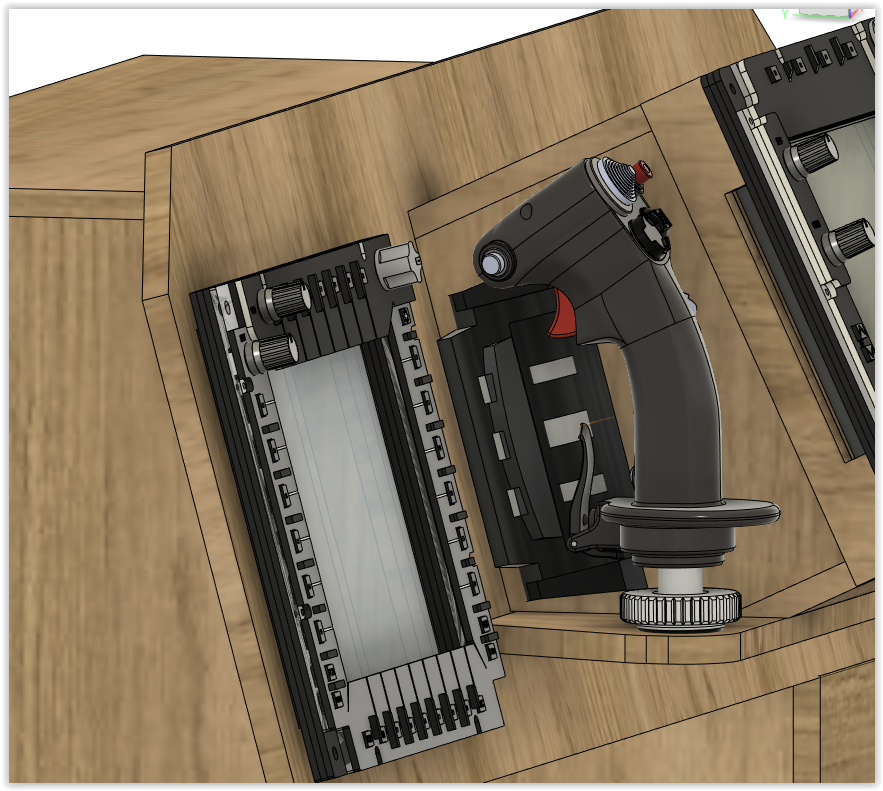

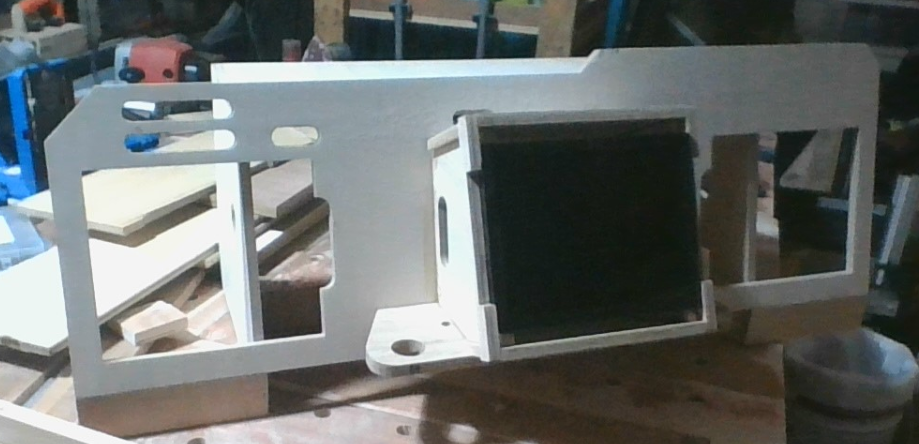

The thing about scale is… it looks good on paper, but then once you’ve built it…. it’s too late, so before i got carried away i wanted to ensure that the primary tool was going to be comfortable, this was the TEDAC/TADS setup, so the first thing i did was cut the grip moutning bracket & sat the 2 grips & the intended TADS screen to get a feel for it.

Glad I did, I ended up adding a little to the dimensions just for ergonomics.

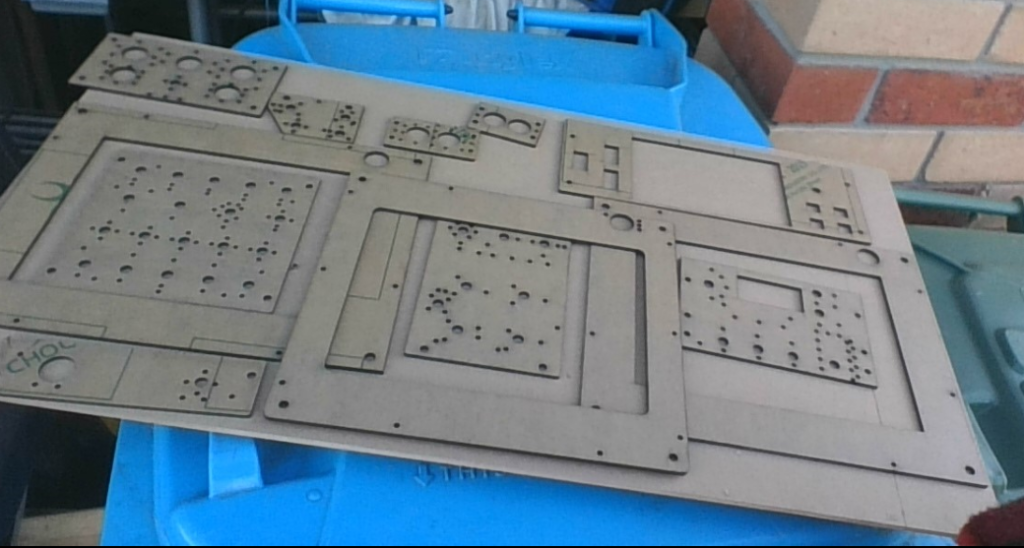

Once happy with the mount dimensions, i had to tweek the remainder of the pieces to reflect the slight changes, then i could begin cutting everything out

sadly regardless of which mill bit I use, there is always lots of sanding still required…. sanding….. sanding……sanding.

It is always nice to see a project take shape.

Now i could investigate how well the base of each stick would sit & set the perfect height so that it was easily reachable by a reaching out with the fingertips whilst resting on the TEDAC grips.

At the same time i needed to make sure the factory supplied cable lengths were suffice to thread through the TADS mount to get back to the PCBs from each base that were now housed in behind the TADS screen. fortunately i only had to lengthen one of the wire looms, I probably could have gotten away with it, but there is always something that needs maintenance, & not being able to easily remove a component or at least set it aside whilst still connected is a pain, always try to give yourself a bit of slack. You’ll be grateful for it one day.

I cannot explain how much I hate painting, i thik it’s mutual as I always seem to end up with more up my arm & in my hair than i do on the brush. So spray cans it is…. I must admit though, a simply lick of paint makes all the difference.

First top coat, to give it that intended end result.

Now for the fun stuff, mounting up & connecting all the components

Wood screws placed in strategically located imporovised mounting holes so as not to hit anything vital….

placement of this base required longer screws at the rear of the base section, having the powerdrill that close resulted in marking the panel…. not to worry, more touching up to come.

Mounting each grip & threading the wiring through the access holes back to the PCs is a bit of a catch 22, as some of the grip wiring runs under the mount, then back up & behind the base sections & into the TADS mount to the PCB, couldn’t make it too easy.

Reaching around the grip & trying to lift a loosely secure base section to thread the wire through is problematic enough without short wiring & fat fingers….

Once the grips were in place I was ready to mount the displays & conduct the first test.

These displays are very clear & just beautiful. Config is easy, no real problems encountered. They will not run on USB power though, so you might need a 12V power supply, if you have an old PC power supply, cannabilise it to run these panels & all the back lighting in your pit…

Time to start fabricating the MFD panel layers to hold the displays in place

All my panel production is pretty much the same method as used by the Warthog project (why reinvent the wheel). It works as advertised.

I was only supposed to be making the MFD base layers to hold the displays in, but instead i ended up with full sets for the Fire Extinguisher, Master ARM & Master Caution panels…..

Now back to our regular programming…. .that’s what I was supposed to be doing.

Nothing really noticable changed here, other than the giveaway of the pack of threaded inserts in the bottom corner. I drilled & placed inserts for the panels to mount into so that they wouldn’t fall out & get damaged.

More thread insert placement, this time for the EUFD, I included the CMWS, but I don’t think it will allow me to acti0n these inputs (even with a panel with switches mapped) from the CPG station. I have yet to test this, but I had made the panel so I thought I’d mount it anyway, just in case.

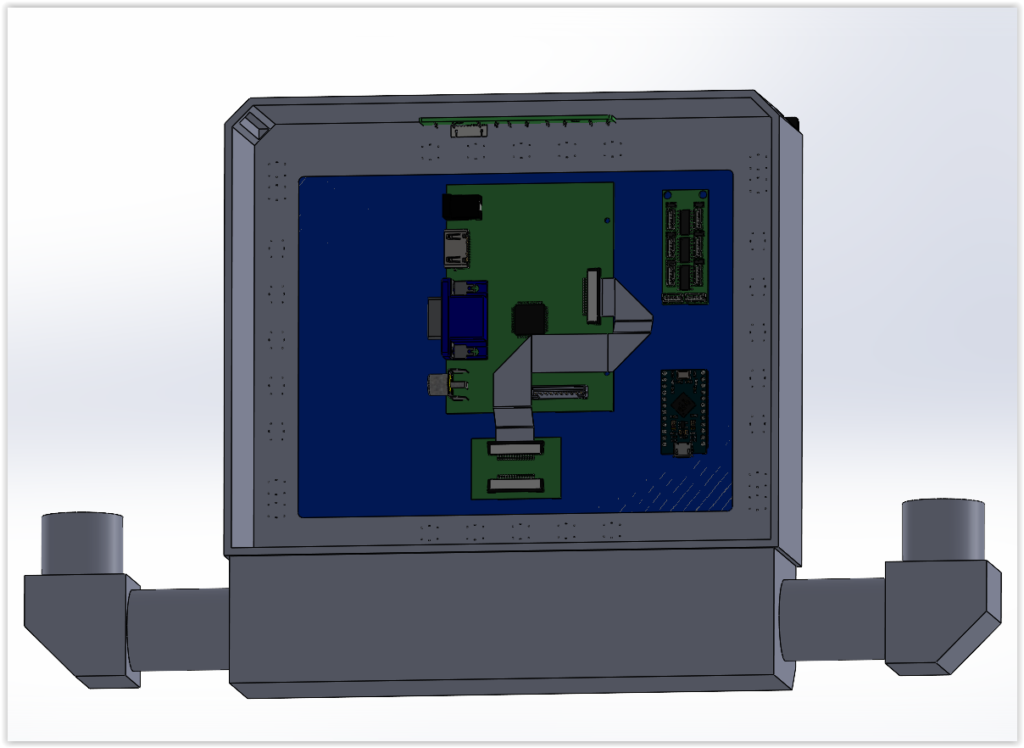

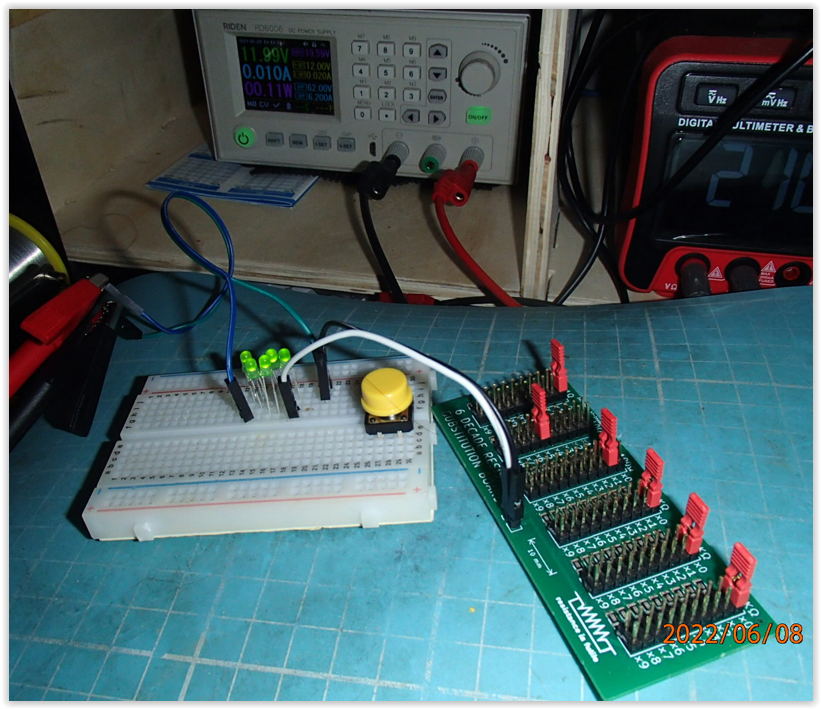

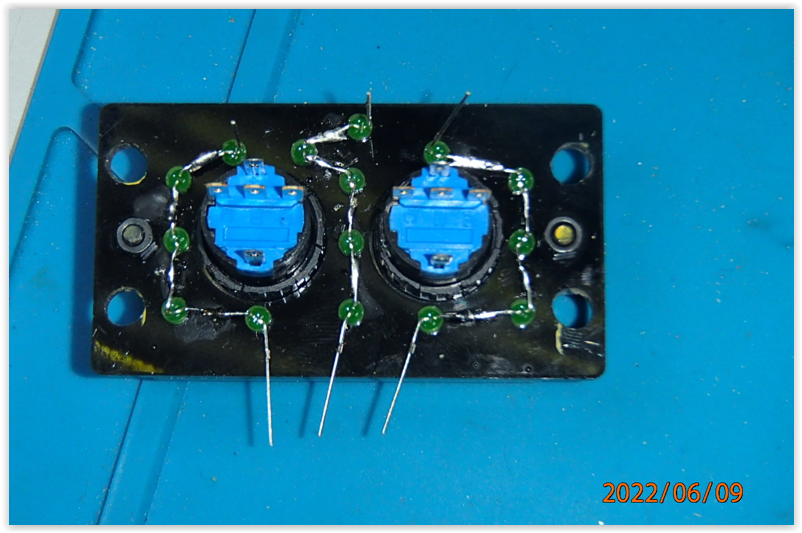

In preparation for the LED back lighting of all the panels, I need to determine the resistors required for each LED string. the small board to the right is a decade board, which allows you to create a ‘custom’ resisitor based on your circuit requirements if you don’t have a specific resistor

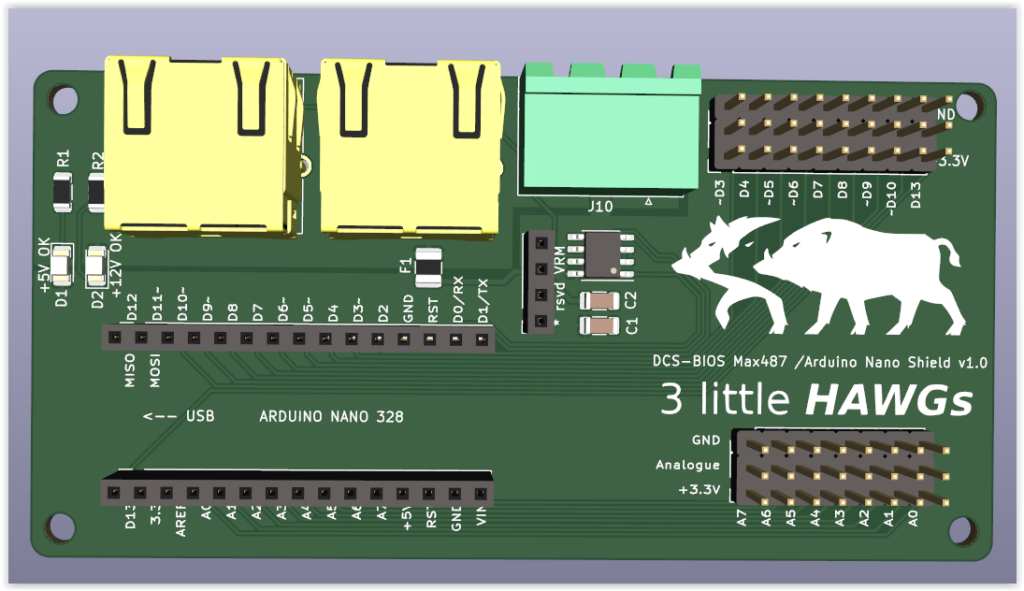

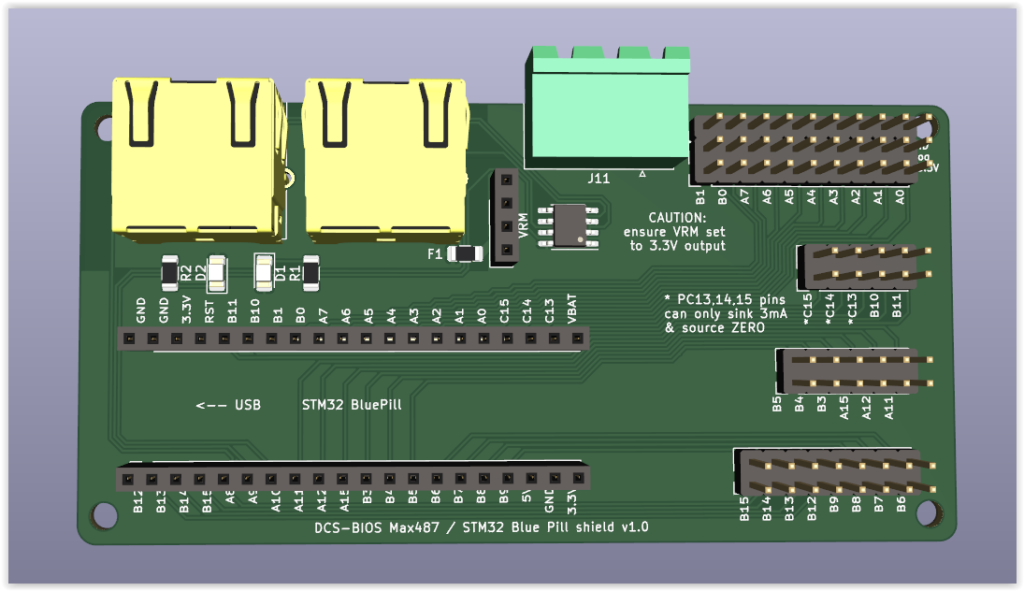

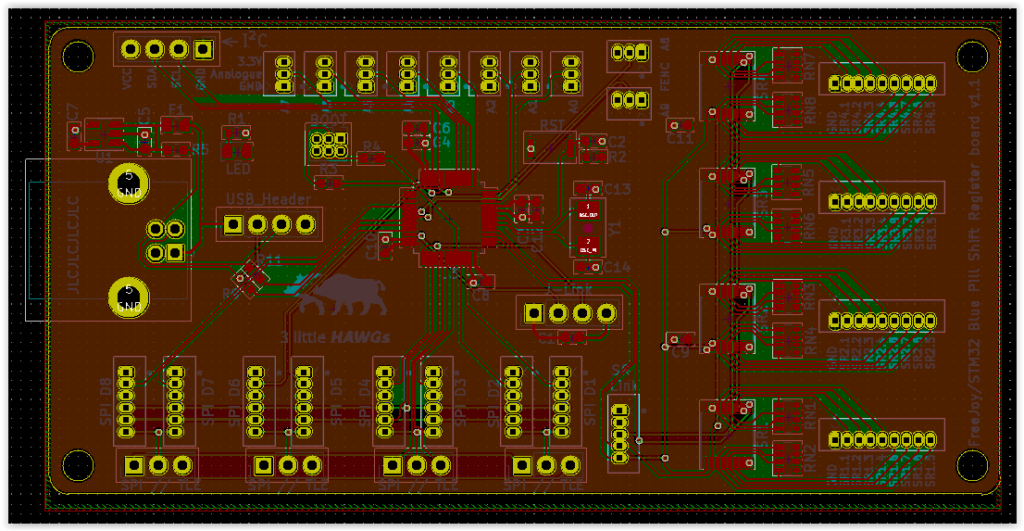

My colleague designed & had this board fabricated as part of his learning curve of using KiCAD, submitting a board for prototyping, including fabrication, so a bill of materials as well as a pick & place file was required. All new ground for us & he did a great job using this small/handy project to test out this process.

Very clever indeed

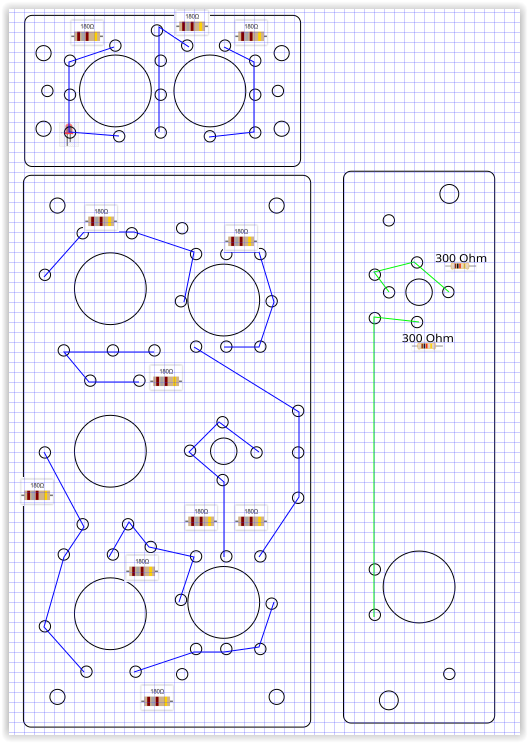

Due to the number of backlights required & the sequencing of max 4 LEDs per string, I also had to plan out optimal string patterns for each panel

This diagram was when I was assuming i could get up to 5 LEDs in a string, until I realised the Captain Obvious that this wasn’t achievable…it’s hard to find good help

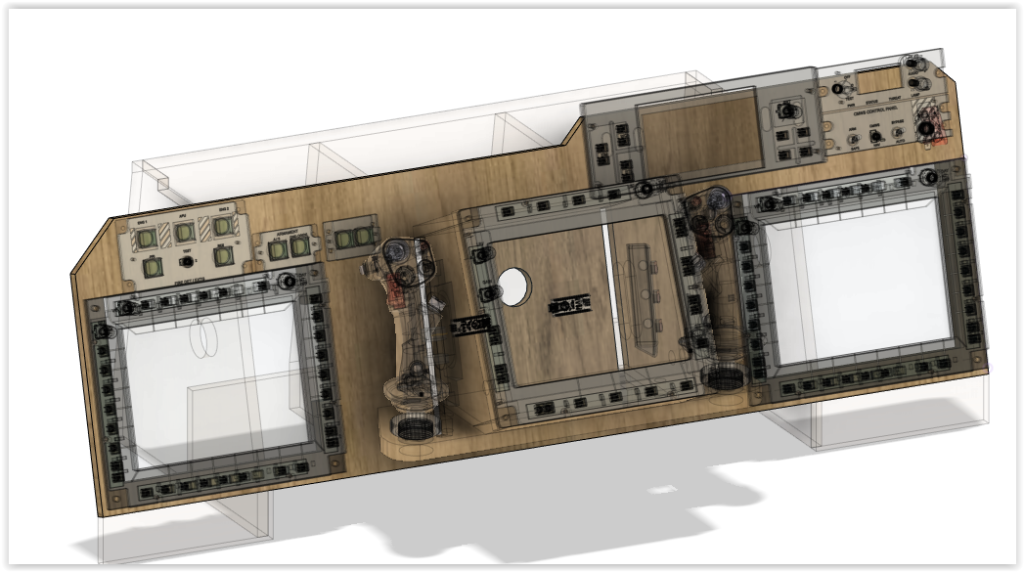

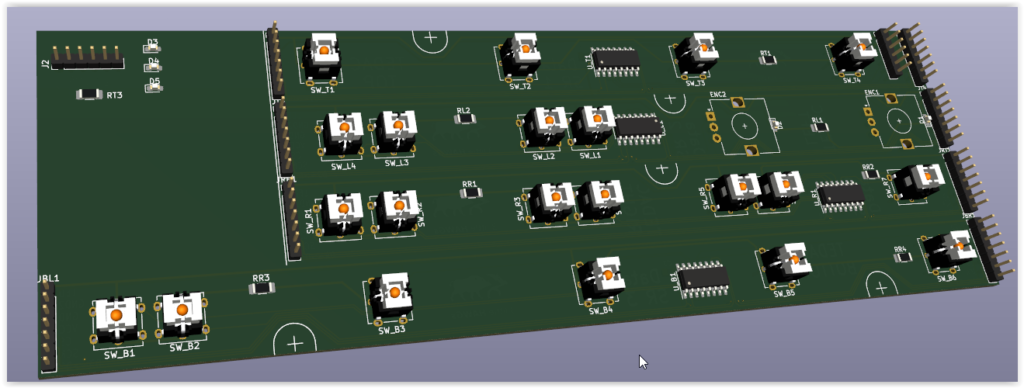

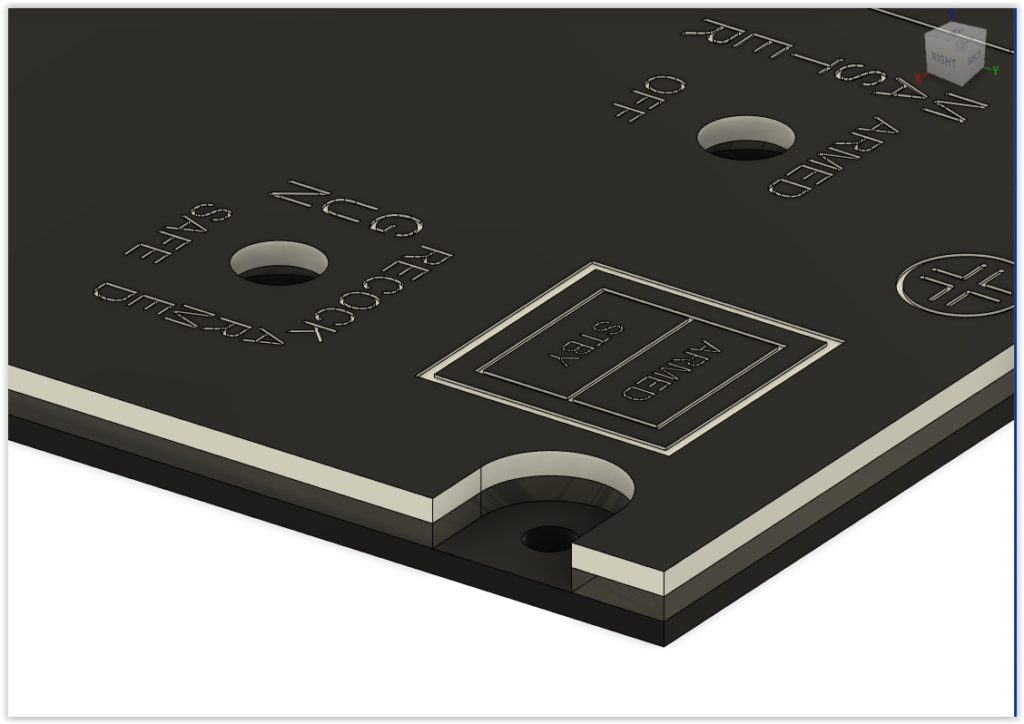

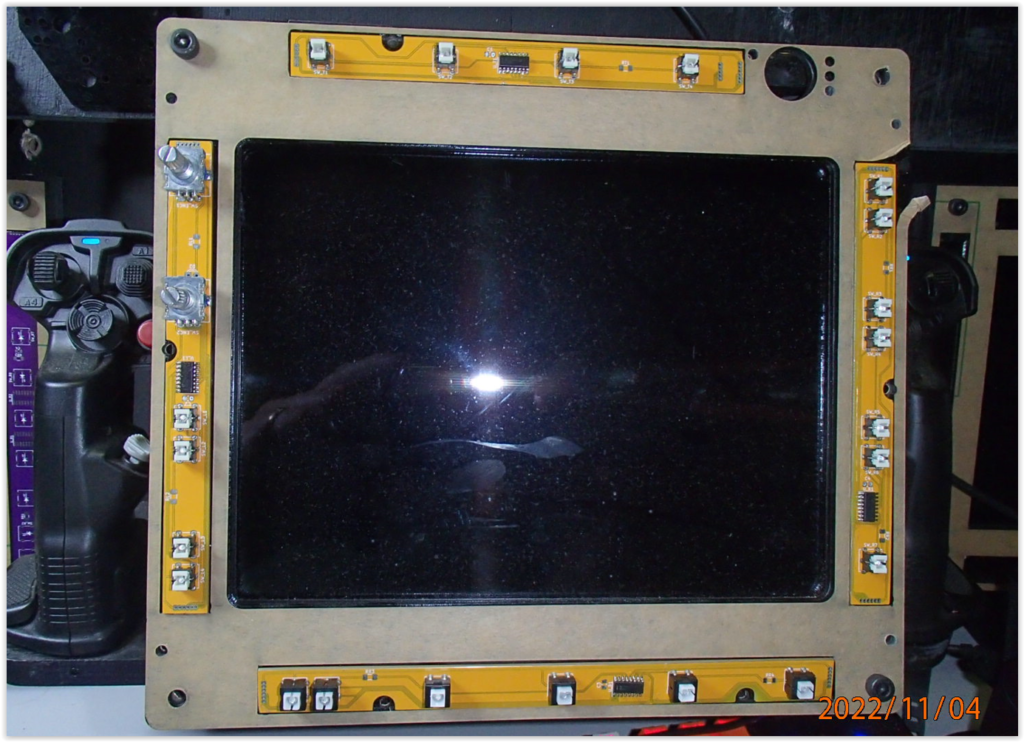

Added an additional layer to the MFDs & TEDAC panels showing the location of the custom PCB strips that will provide the button mounts for each panel

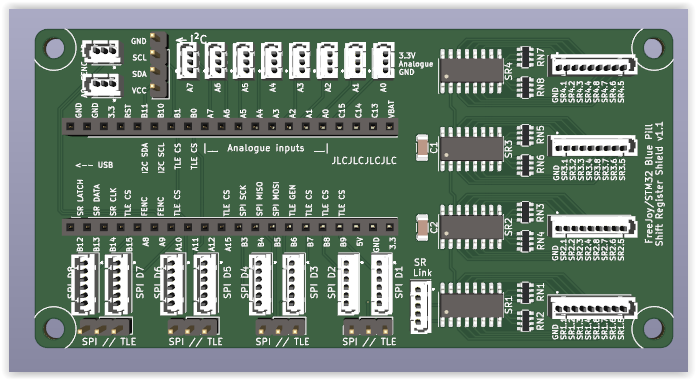

each PCB strip is slightly unique unfortunately, so I had to make a set of all 4, with each button, as well as screw holes to accommodate the layer construction.

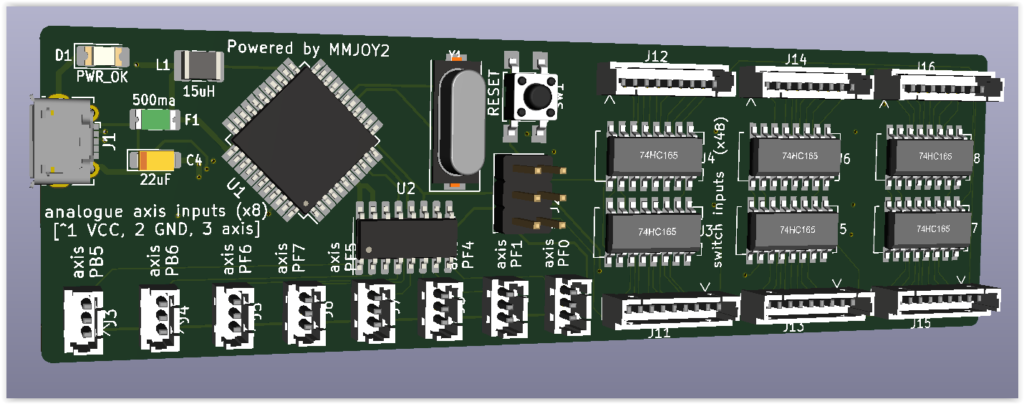

Each PCB strip has a localised Shift register, so that regardless of the number of buttons, there will only be 5 wires running between each of the strips & then back to the microcontroller (FreeJoy) board.

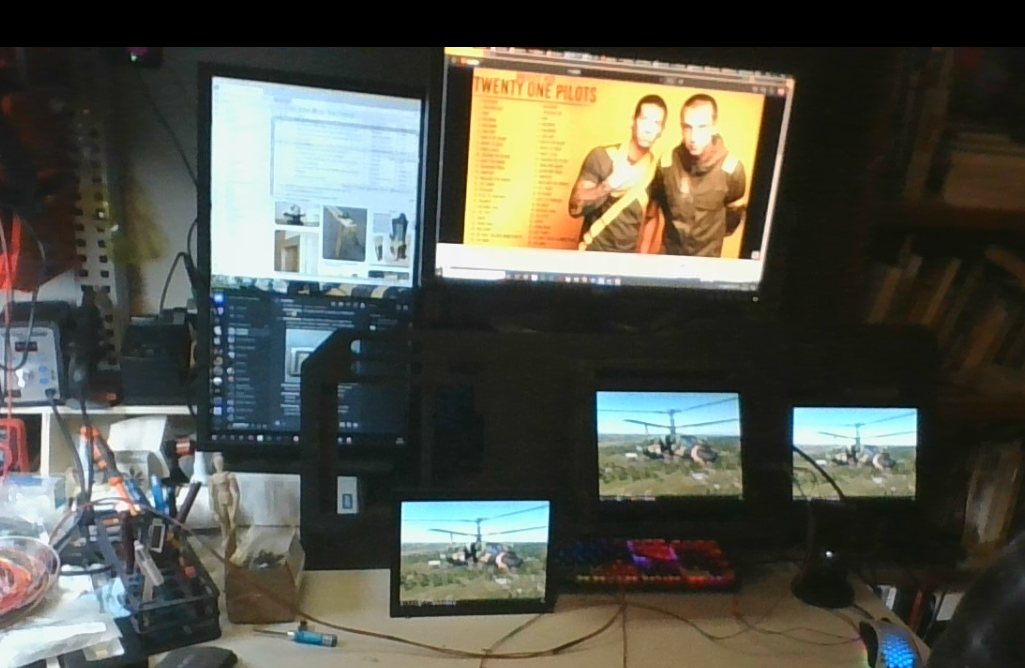

Now to try & get some screen output happening

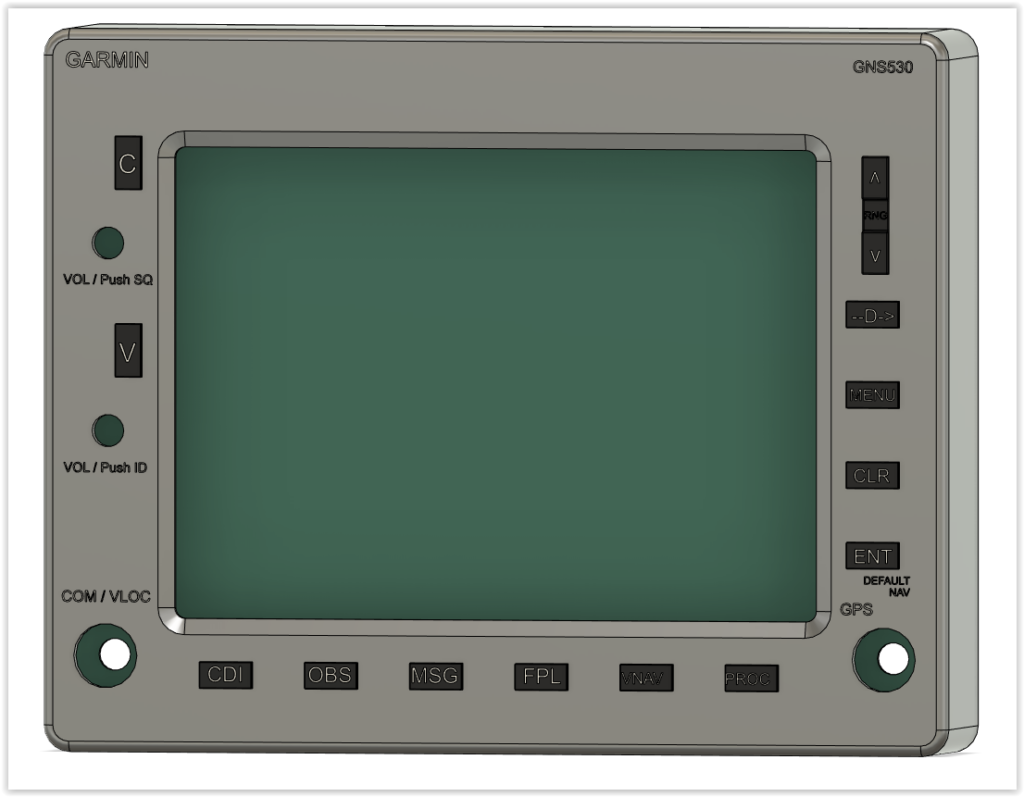

Initially I was only able to get the 2x MFDs working using Helios, despite several attempts to get the TADS output, I wasn’t able to achieve this, but we saw on the Flight Panels fork that the TADs was coming in the next realease, so i busied myself with other things to keep me occupied.

I was a little concerned with how dim the MFDs were, but with a little tinkering inside the game I realised my faux pas & all was well.

To confirm there was nothing wrong with the centre screen & that Helios was otherwise unaffected I tested out the F-18

I know, a filthy fixed-wing, but it had to be done to validate the otherwise working config.

Onto painting the switch caps

The switch cap can be easily removed from the switch by gently pulling it straight out, take care to not the orientation of the small tabs at the end of the switch cap when orientating them to place them back into the switch

I made a multilayer jig to spray the push button switches with a flat black paint, then once dried I could flip the jig over & placed them in the recessed side, to laser etch each button label. The middle layer of this jig has slots on the sides to ensure the switch cap can only be orientated up or down, but cannot be placed in at 90 degrees (Left or Right), otherwise laser etching of labels will be… cock-eyed

Holding the jig up to the sun was proof or back lighting

I made an additional jig for painting the switch cap covers (APU & Fire Extinguishers) matte black but leaving a clear stripe down the centre.

Worked a treat.

I began constructing more of the larger panels, the light panel took me a could of goes, the first time I laser etched the incorrect label set on it….. oops.

As per the Warthog Projects assembly, each of the panels is a tri-layer fabrication;

- base layer solid black (to prevent light bleed & mount point for LED)

- mid layer transparent ( to diffuse light, also has hole for mounting LED)

- top layer translucent white, with painted surface ( to block light where not required but allow light diffusion to laser etched labels)

It was at this point after assembling some of the panels & prior to putting the switches in place, I decided to give each top layer a spray with a clear acrylic to protect the laser etching of the black paint layer, this however proved problematic.

As can be seen above the clear lifted the black paint from the top surface.

So i had to dismantle these panels, then sand the surface paint off, reapply the black paint, allow to dry, re-etch, then reapply the clear acrylic. Still getting mixed results in some cases. So i ended up recutting the top layer of some of the panels & repainting, re-etching, etc. SNAFU

Helios updated & I could finally get the TADS output I so sorely desired, starting to really get the itch now. Cannot wait to get my MFD buttons working also

I took this opportunity to also map the controls for the TEDAC grips so that I could tinker a little bit in DCS.

Enough distractions, on with the build, I finally got my next screen delivered & configured it up to serve as the EUFD, gave it a test/base screen to look like a running EUFD so I could verify font size & spacing.

Ran up DCS with DCS-BIOS also running & confirmed all the output displayed & worked as expected. Eureka

Must admit, this was a nice little goal post to get past. The panels are cut for the EUFD, but I am also designing some small custom PCBs to mount the switches on, which are in the queue, but behind the TEDAC/MFD custom PCB strips

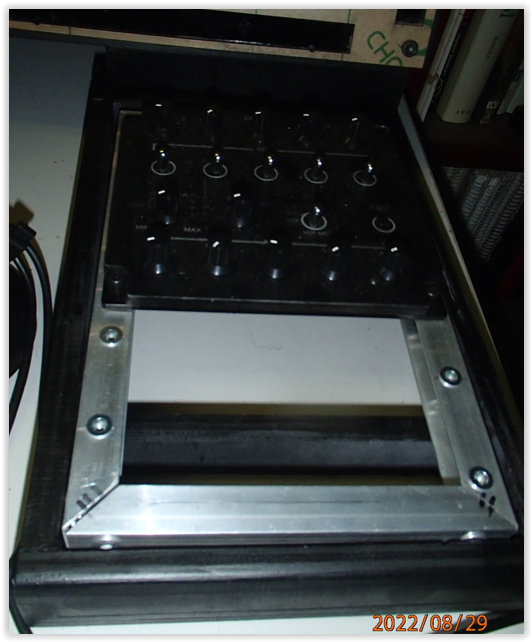

As I continue to fabricate more of the panels for the side consoles, they are getting knocked about a bit as I move one project pile aside to work on another, so I decided to make the mounting frames for them to give them something to sit in & hopefully protect them from any damage.

Frames are simple aluminium 15mm C channel, available at Bunnings, in order to fabricate these & not cock up any measurements, I laser cut cardboard templates of each panels base layer along with a pinhole marker for the centre of the mounting holes.

I sticky taped these together then measured the lengths for the side pieces & confirmed the width dimension for top & bottom sections. Cut them, marked drilled holes for small L brackets, then pop rivetted the L brackets ensuring that the frame retained as close to square as possible.

I then took the sticky-taped cardboard panel set, placed them central on the frame & taped them down so they wouldn’t move.

I placed the aluminium frames in a small square jig using my parf system on my benchtop to keep the frame as square as possible. At this scale a few mm isn’t going to matter much, but you know…. OCD

I used a centre hole punch to mark the aluminium frame, then removed the cardboard templates.

Using my drill press I the pre-drilled each hole with a pilot drill to get best result of centre, then changed up to a 6mm drill to bore the holes for the riv-nuts.

Note: Aluminium Riv-Nets are not the most robust things so you need to take care when putting them in to not tear the thread out of them, which renders them entirely useless…. don’t ask me how I know

Once the riv-nuts were inserted, the panels for each side console could them be put in place & secure with M4 hex cap head screws.

At the same time i did the aluminium frames, I also fabricated the top dash protrusion, gave it a lick of paint & put all the threaded inserts in place.

Once the undercoat dried I gave it a coat of black & ran a rubber U -trim along the forward edge to give it that finished look. Came up looking the goods.

Now to mount it all up

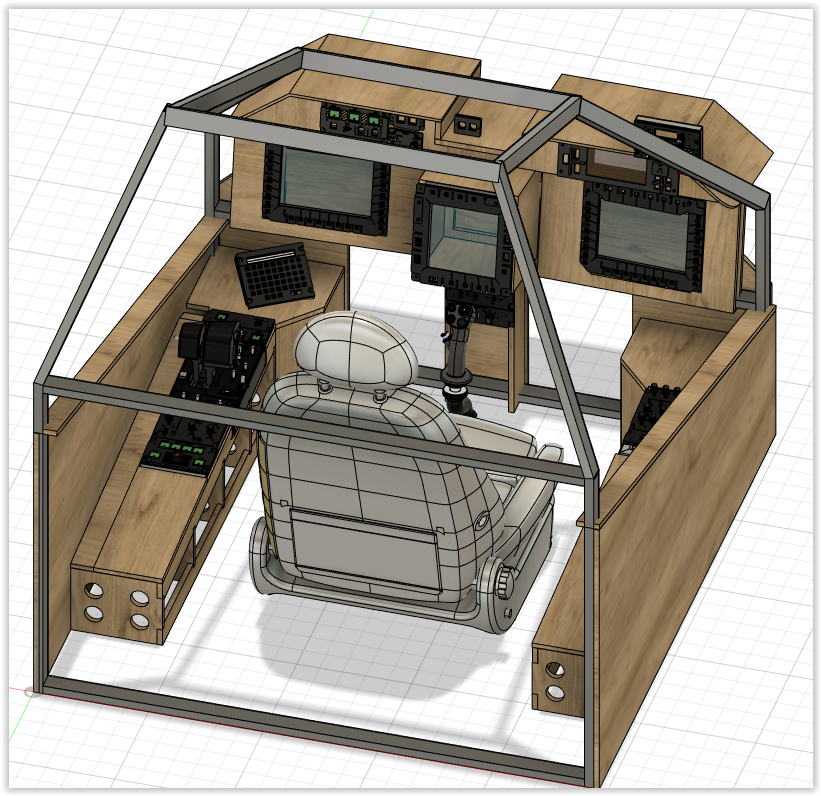

The dash protursion is a big difference in asthetics, one of the driving factors for including this is the addition of angled mounts for the L & R MFDs to pan them back around to towards the CPG. this also made a big difference when sitting in front of the dash. Its amazing what a difference jsut a few degrees can make.

I finally got around to making side sections to seat the side console frame panels. lifting the switches up off the desktop & also allowing me to place the Streamdeck XL where the Keyboard Unit would go. At this point I am not going to make a KU until I am further along with the simpit design.

2 non-essential panels still missing from the RH console, they will be populated eventually.

The RH console only just fits in the desktop depth, so I am unable to tilt the streamdeck / pseudo KU , but in this instance, it’s no biggy, the consoles now in place I can begin wiring them all up once I get my FreeJoy board prototypes.

Should be here this week touch wood. It will be great to finally get everything wired up.

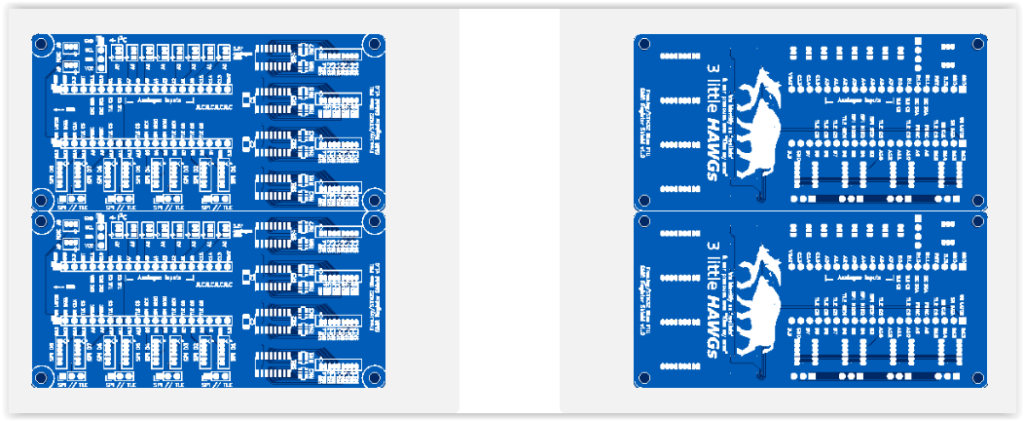

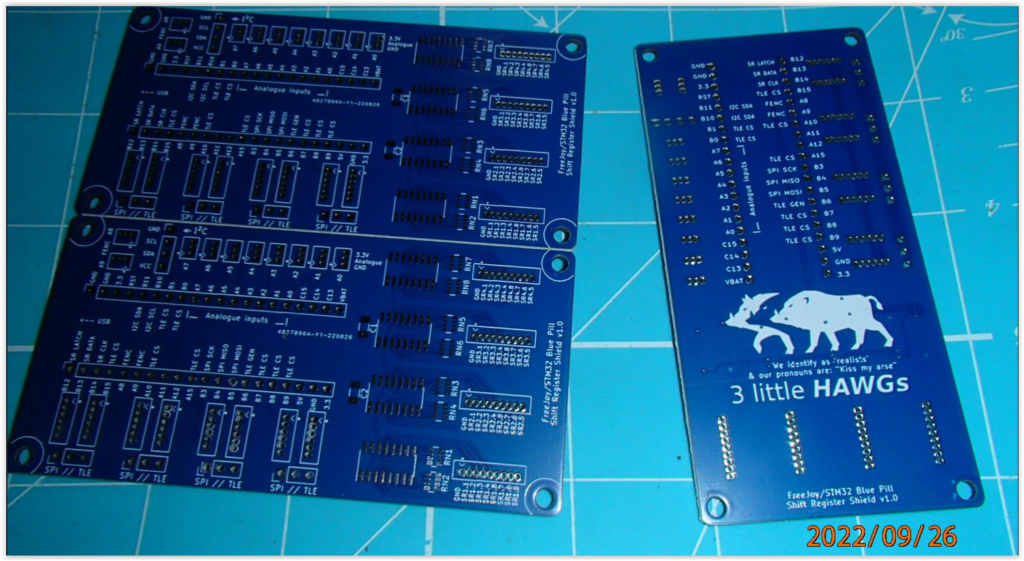

Freejoy PCBs arrived, unfortunately I do not have 100% of the required components, ironically specifically the smallest & hardest to get to ones, so any assembly preceding that would be counter-productive.

another case of hurry up & wait in a post covid-19 world….

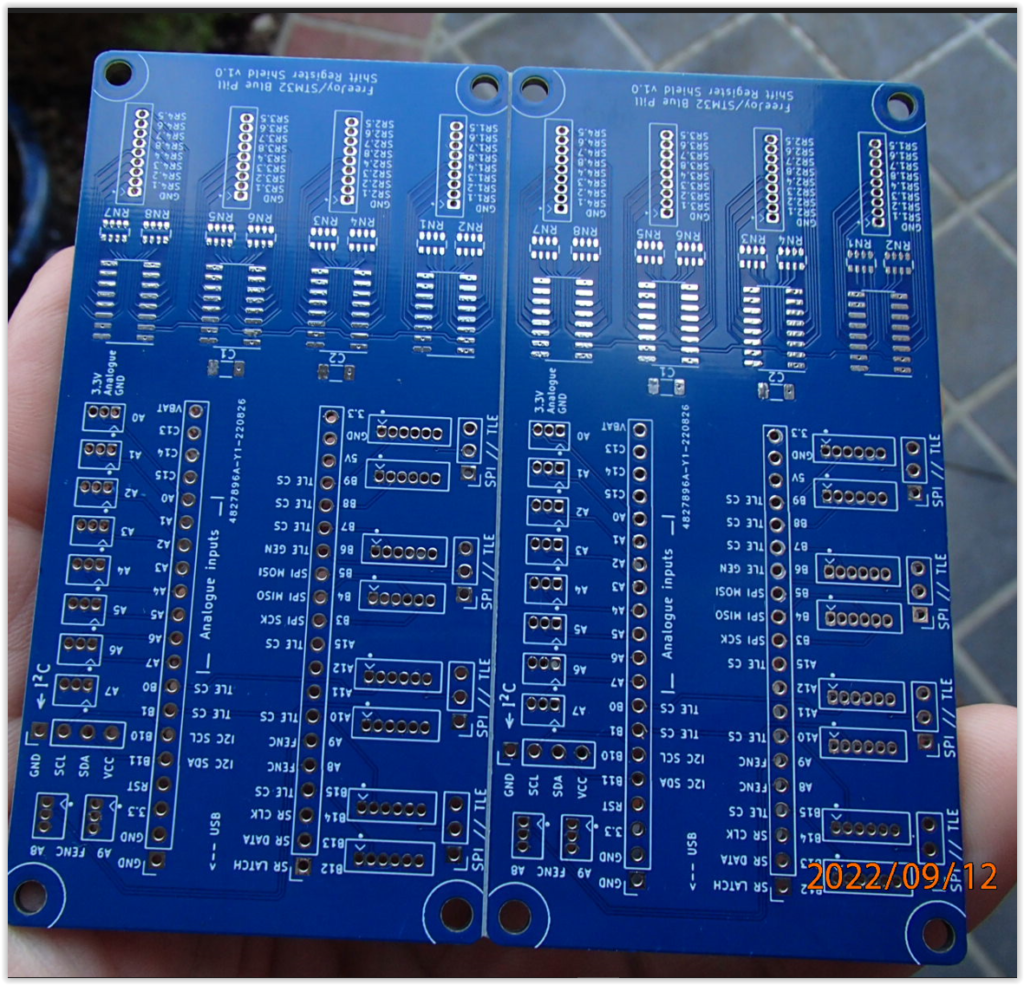

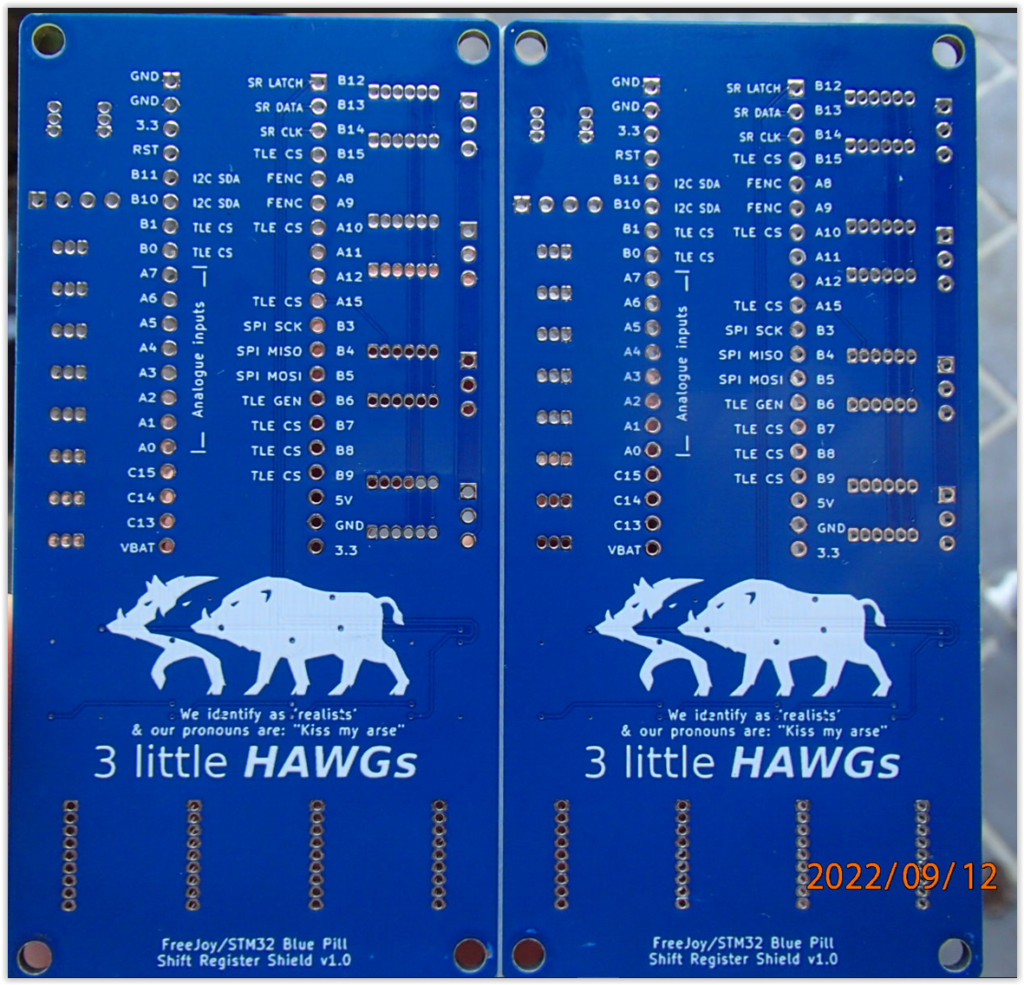

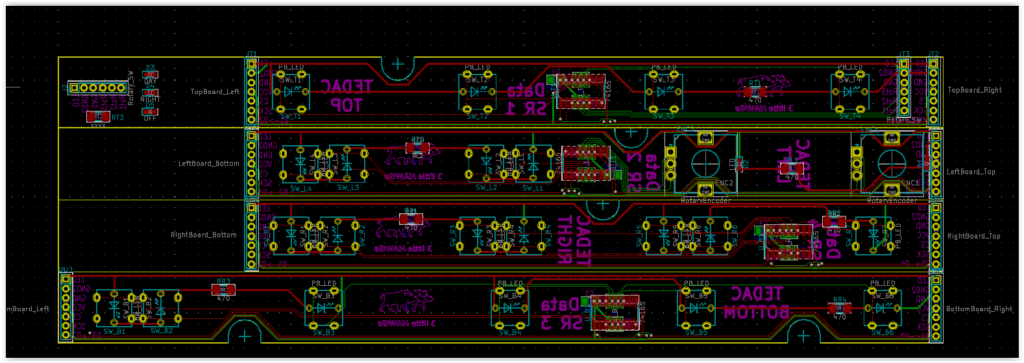

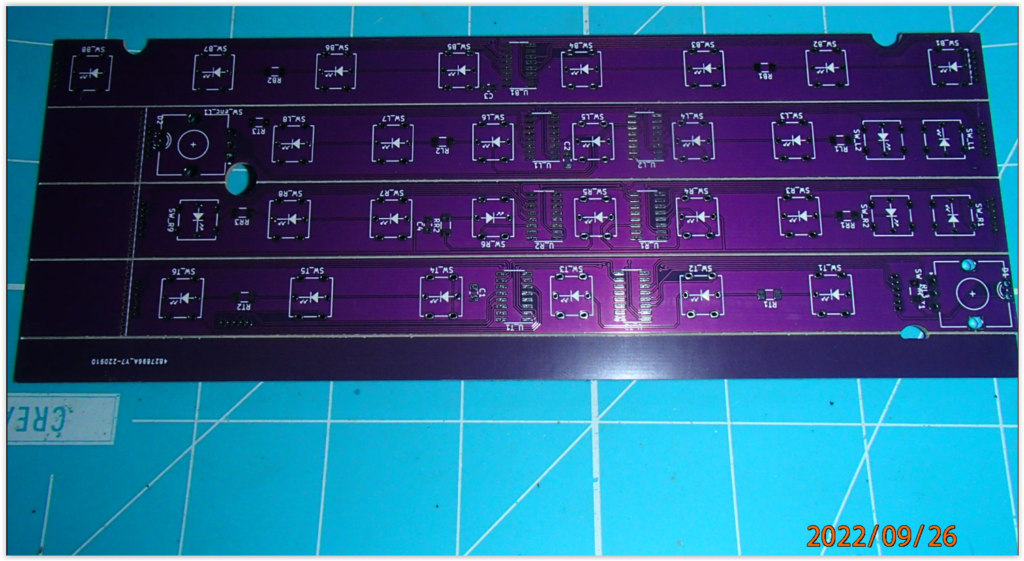

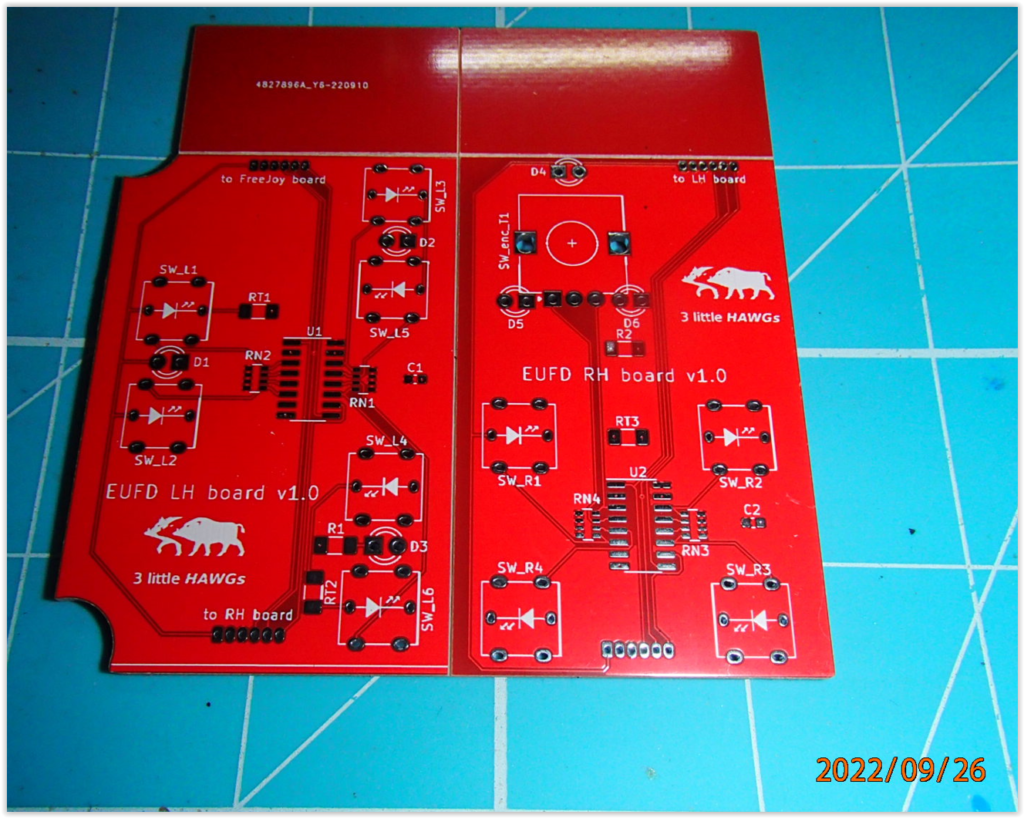

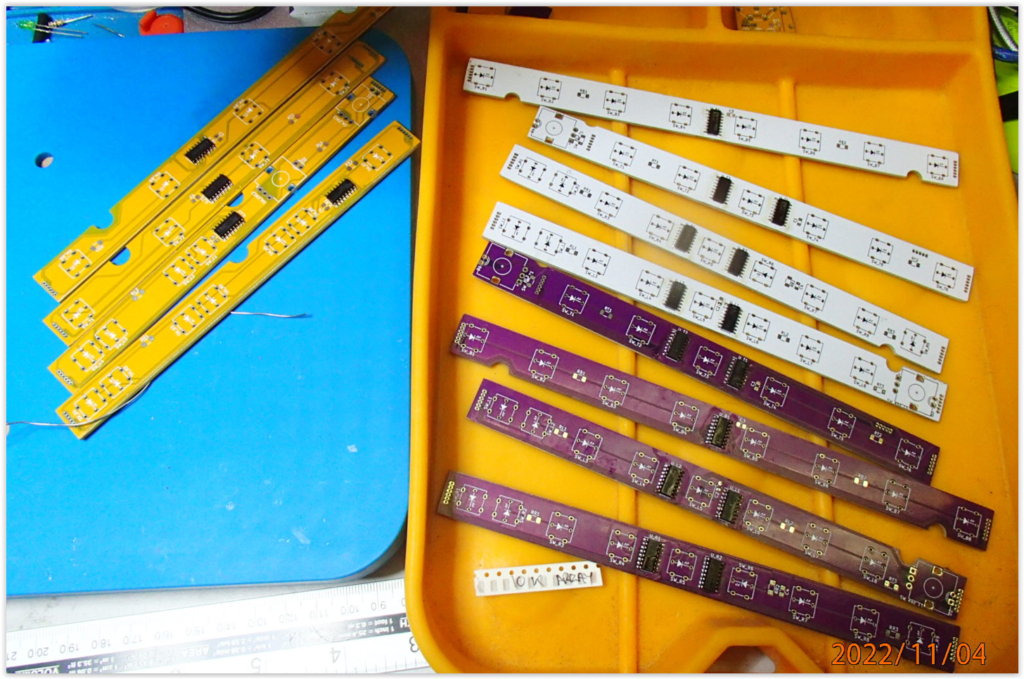

additional PCBs were also designed & sent off & have arrived as well.

each done in a different colour for no specific reason other than to test out how each one looks, in terms of aesthetics, silk screen readability, as well as ease of troubleshotting (trace following etc).

MFD strips in purple & EUFD in red…

TEDAC MFD in white with black silkscreen….

A little bit of a hiatus as I’ve been waiting for rain to subside so that I could get my workbench out in order to continue work on the PCB strips; seperating them, sanding & cleaning up edges, & now soldering/assembly.

The initial hurdle was soldering the SMD resnets & Shift Registers to the strips… impossible (for me) without solder paste, heat gun, digital microscope & a very good iron

The Shift Registers are easy in comparison….

The MFDs are getting so close to being usable…. I can taste it.

| Left MFD strips with switches | Right MFD strips with switches |

|  |

The left & Right MFD PCB strips are different colours for no real reason, other than I mistakenly ordered 2 sets of prototypes of the same board but in a different colour…. oh well, lemonade from lemons; I can now build 5 complete sets from the protoype boards, (if there is any demand for them).

I still have to put a few more SMD components on each strip, (a couple of resistors & the odd capacitor + the odd LED…then the connectors) but for the most part, these PCBs are just about done & ready to test….

& potentially let the ‘magic’ smoke out…..