Working on the solutions to provide the input controls as well as the lighting and output from DCS into our colleagues A-10C cockpit, we have come up with several ideas to provide a suitable, scalable & maintenance friendly solution to this, but hadn’t gotten very far when , once again we stumbled upon a very interesting post on the ED forums by Hansolo

https://forum.dcs.world/topic/208455-dcs-bios-over-rs485/

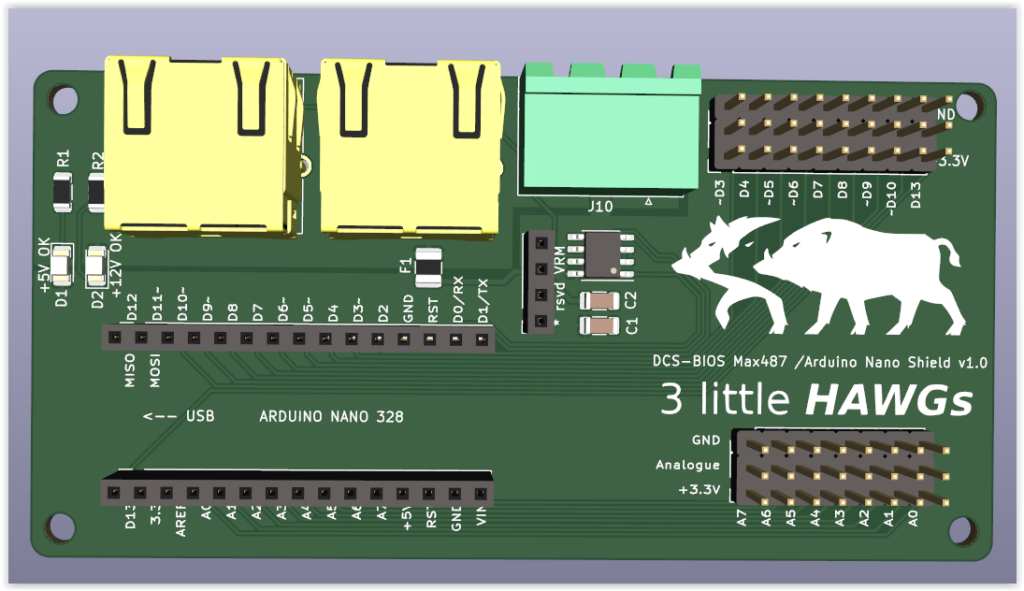

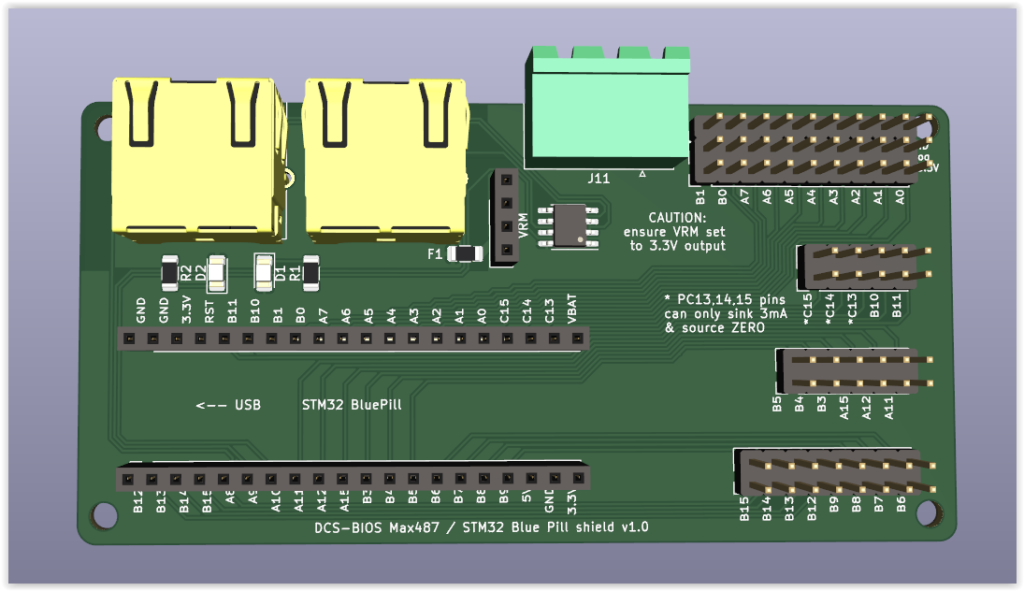

The quality & detail of this post is admirable, & follow up posts by forum members showing just how creative this sim community is, with several examples of custom PCB shields, which put us on the path of developing our own, once again based around the STM32 bluepill, to rationalise the different microcontroller cards we would be required to source.

DCS-BIOS slave boards

Being that we also already had several arduino nano boards, & the cost of producing a limited batch of these boards under prototype pricing is trivial amounts (<AUD$10 for 10 boards).

The primary goal here was to utilise the STM32 bluepill so a similarly laid out shield board was also produced to suit it.

Note that both of these DCS-BIOS slave shield boards have pin sockets for a Voltage Regulator Module sub-board to filter the 12v input, whether via the RJ45 or power connector & provide a more reliable 5V or 3.3V respectively.

DCS-BIOS master board

At the time of writing the DCS-BIOS master panel is only viable with an Arduino Mega 2560 card, due to the requirement of more than one TX/RX bus.

The Mega2560 is comparatively expensive option to the STM32 bluepill, which also has more than 1 TX/RX, so we are pursuing a solution where the STM32 bluepill can act as either the master or slave nodes in this framework, again attempting to rationalise MCU types & reducing overall variables & additional cost.

If the end result that the STM32 is not supported as the DCS-BIOS master node, then we will also need to design & produce a DCS-BIOS master shield to suita Mega 2560.

For the connection cables we selected RJ45 connectors as the leads are readily available & we have the tools to terminate custom cable lengths as required.

12V will need to be run to provide power to the LED backlighting throughout the cockpit, this can be run either through the RJ45 cable, or alternatively directly via the power connector on the shield board